Heat Press Manual PDFs⁚ A Comprehensive Guide

Heat press manuals are essential guides for anyone using a heat press to create custom apparel, mugs, plates, or other items. These manuals provide detailed instructions on how to operate, maintain, and troubleshoot your heat press, ensuring safe and effective use.

Introduction

Heat press manuals are indispensable resources for anyone using a heat press for various applications, such as creating custom apparel, mugs, plates, or other personalized items. These manuals are designed to provide comprehensive guidance on operating, maintaining, and troubleshooting your heat press, ensuring safe and efficient use. They serve as a valuable reference point throughout the entire process, from initial setup to ongoing maintenance.

Heat press manuals cover a wide range of topics, including safety precautions, temperature calibration, pressure adjustment, and proper application techniques for different materials. They also offer helpful tips for achieving optimal results and troubleshooting common problems that may arise. By adhering to the instructions outlined in the manual, users can maximize the performance of their heat presses and produce high-quality, professional-looking results.

The availability of heat press manuals in PDF format has revolutionized accessibility and convenience. Users can readily download and access these manuals online, eliminating the need for bulky paper copies. This digital format allows for easy storage, sharing, and referencing, making it a convenient and practical resource for heat press enthusiasts and professionals alike.

In the following sections, we will delve deeper into the various aspects of heat press manual PDFs, exploring their significance, content, and benefits. This comprehensive guide will provide valuable insights for anyone looking to enhance their understanding of heat press operations and maximize their potential for creating unique and personalized items.

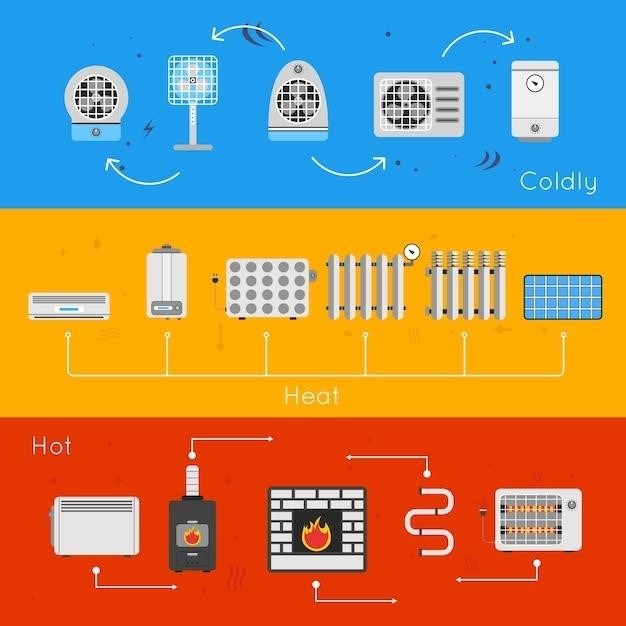

Types of Heat Presses

Heat presses come in various types, each designed for specific applications and materials. Understanding the different types of heat presses will help you choose the right one for your needs and effectively utilize the information provided in the heat press manual.

Manual Heat Presses⁚ These are the most basic and affordable type of heat press. They require manual operation, with the user manually applying pressure and controlling the time and temperature settings. Manual presses are suitable for smaller-scale projects and hobbyists.

Automatic Heat Presses⁚ Automatic heat presses offer greater convenience and precision. They feature automated functions, such as pressure application, timer controls, and temperature regulation. Automatic presses are ideal for high-volume production and professional applications, where consistency and efficiency are paramount.

Swing Away Heat Presses⁚ This type of heat press features a swing-away design, where the upper platen swings away from the lower platen, allowing for easy access to the work area. Swing-away presses are commonly used for apparel and other flat items.

Clamshell Heat Presses⁚ Clamshell presses have a clamshell design, where the upper platen closes down onto the lower platen, similar to a clamshell. Clamshell presses are suitable for various applications, including mugs, plates, and apparel.

Specialty Heat Presses⁚ Specialty heat presses are designed for specific applications, such as mugs, caps, plates, or even large-format items. These presses feature specialized platens and pressure systems to accommodate the unique shapes and sizes of the materials they are intended for.

Each type of heat press comes with its own set of features and capabilities, and the corresponding heat press manual will provide detailed instructions on operating and maintaining each specific model. Understanding the type of heat press you own will ensure that you use the manual effectively and achieve optimal results.

Common Heat Press Manufacturers

Several reputable manufacturers produce a wide range of heat presses, each with its own unique features and capabilities. Understanding the common heat press manufacturers will help you identify the brand of your heat press and locate the corresponding manual. It will also provide insights into the quality and reliability of the equipment.

Stahls Hotronix⁚ A leading manufacturer of heat presses in the United States, Stahls Hotronix offers a comprehensive line of heat presses, including manual, automatic, and specialty presses. They are known for their high-quality, durable equipment and excellent customer support.

Geo Knight⁚ Another prominent American manufacturer, Geo Knight specializes in industrial-grade heat presses designed for commercial and industrial applications. Their heat presses are built for heavy-duty use and offer high levels of precision and consistency.

Hotronix⁚ Hotronix is a subsidiary of Stahls’ and is renowned for its innovative heat press technology. Their heat presses are designed for various applications, including apparel, mugs, and other items. Hotronix manuals often include detailed technical information and troubleshooting guides.

The MAXX⁚ The MAXX is a popular brand of heat presses known for their high-quality construction and user-friendly design. Their manuals provide comprehensive instructions on operating and maintaining their presses, including safety precautions and troubleshooting tips.

Phoenix⁚ Phoenix is another reputable manufacturer of heat presses, offering a range of models for different applications. Their heat press manuals often include detailed diagrams, step-by-step instructions, and helpful tips for achieving optimal results.

These manufacturers represent a cross-section of the heat press industry, offering a wide range of products and services. Familiarity with these common heat press manufacturers will aid in locating the correct manual for your specific heat press model, ensuring safe and efficient operation.

Essential Features of a Heat Press Manual

A comprehensive heat press manual is more than just a collection of instructions; it’s a vital resource for safe and successful heat transfer projects. These manuals should provide detailed information on various aspects of operating and maintaining your heat press, ensuring optimal performance and longevity.

Safety Precautions⁚ This section should highlight essential safety practices when using a heat press. It should cover topics like appropriate clothing, proper ventilation, and the importance of wearing heat-resistant gloves. Additionally, it should address potential hazards like burns and electrical shock, emphasizing the need to follow all safety guidelines.

Operating Instructions⁚ This section should provide clear and concise instructions on how to operate the heat press, including setting the temperature, time, and pressure. It should also explain how to calibrate the heat press to ensure accurate temperature readings.

Troubleshooting Guide⁚ This section should address common problems encountered with heat presses, such as inconsistent heat distribution, malfunctioning pressure settings, or timer issues. It should provide step-by-step solutions for addressing these problems.

Maintenance Procedures⁚ Regular maintenance is crucial for extending the life of a heat press. This section should outline essential maintenance tasks, such as cleaning the platen, checking the heating element, and lubricating moving parts.

Parts and Accessories⁚ This section may include information about the different parts and accessories available for the heat press, including replacement parts, attachments, and optional upgrades. It may also provide guidance on ordering replacement parts or accessories.

By including these essential features, heat press manuals equip users with the knowledge and tools to operate their heat presses safely and effectively, maximizing their investment and ensuring successful heat transfer projects.

Safety Precautions When Using a Heat Press

Heat presses are powerful tools that can generate significant heat and pressure, making safety a top priority. A comprehensive heat press manual should include a dedicated section outlining essential safety precautions to minimize risks and ensure a safe working environment.

Personal Protective Equipment (PPE)⁚ Users should always wear appropriate PPE when operating a heat press. This includes⁚

- Heat-resistant gloves⁚ These protect hands from burns when handling hot surfaces and materials.

- Safety glasses or goggles⁚ These shield eyes from potential debris or hot particles that may fly off during the pressing process.

- Long sleeves and pants⁚ These offer additional protection from accidental contact with the hot platen or other heated components.

Work Area Safety⁚ The work area where the heat press is used should be safe and free of hazards⁚

- Stable surface⁚ Ensure the heat press is placed on a stable, flat surface that can support its weight.

- Adequate ventilation⁚ Proper ventilation is essential to dissipate heat and fumes generated during the pressing process.

- Clear workspace⁚ Keep the work area clear of clutter and obstacles to prevent accidents.

Electrical Safety⁚ Always follow these electrical safety guidelines⁚

- Grounded outlet⁚ Connect the heat press to a properly grounded electrical outlet to prevent electric shock.

- Inspect cords⁚ Regularly inspect the power cord for any damage or wear and tear. Replace damaged cords immediately.

- Avoid water⁚ Never expose the heat press to water or other liquids to avoid electrical hazards.

By adhering to these safety precautions, users can minimize risks and create a safe working environment for themselves and others. Always consult the heat press manual for specific safety instructions related to your model.

Troubleshooting Common Heat Press Problems

Even with proper operation and maintenance, heat presses can experience occasional problems. A well-written manual should include a troubleshooting section that guides users through common issues and their solutions. This section can save time and frustration by providing step-by-step instructions for resolving these problems.

Temperature Issues⁚

- Inconsistent Temperature⁚ If the heat press is not reaching the desired temperature or fluctuating, check the thermostat calibration, power supply, and heating element. Refer to the manual for instructions on calibrating the temperature settings.

- Overheating⁚ If the heat press overheats, check for obstructions in the ventilation system or a faulty thermostat. Allow the press to cool down before troubleshooting further.

Pressure Issues⁚

- Uneven Pressure⁚ Uneven pressure can lead to inconsistent transfers. Check the pressure adjustment mechanism and ensure it is working properly.

- Insufficient Pressure⁚ If the pressure is too low, the transfer may not adhere properly. Adjust the pressure according to the manual’s recommendations and the type of material being pressed.

Other Common Problems⁚

- Timer Malfunction⁚ If the timer is not working correctly, refer to the manual for instructions on resetting or replacing the timer.

- Electrical Issues⁚ Check the power cord, outlet, and circuit breaker for any problems. If the heat press is still not working, consult an electrician.

The troubleshooting section of a heat press manual should be comprehensive, covering the most common problems and providing clear, practical solutions. By following these instructions, users can identify and resolve issues efficiently, ensuring their heat press remains in optimal working condition.

Calibrating Your Heat Press Temperature

Accurate temperature calibration is crucial for achieving consistent and successful heat press results. A heat press manual should provide clear instructions on how to calibrate the temperature settings for optimal performance. This process ensures that the actual temperature of the platen matches the displayed temperature setting, preventing over-heating or under-heating of the transfer materials.

Calibration typically involves using a heat-resistant temperature strip or a digital thermometer to measure the actual temperature of the platen. The manual will specify the target temperature for the calibration process, and users need to adjust the heat press’s settings until the measured temperature matches the target.

Here are the general steps involved in calibrating a heat press temperature⁚

- Set the Target Temperature⁚ Choose a target temperature as recommended in the manual or based on the specific transfer material being used.

- Heat the Press⁚ Turn on the heat press and allow it to reach the target temperature.

- Measure the Temperature⁚ Use a heat-resistant temperature strip or a digital thermometer to measure the actual temperature of the platen.

- Adjust Settings⁚ Compare the measured temperature with the target temperature. If there is a discrepancy, adjust the heat press’s settings accordingly.

- Repeat Calibration⁚ Repeat the measurement and adjustment process until the measured temperature consistently matches the target temperature.

Calibration should be performed regularly, especially after prolonged use or when the heat press has been moved or stored. By accurately calibrating the temperature settings, users can ensure consistent and reliable heat press performance, leading to successful and professional-looking transfers.

Using a Heat Press for Different Applications

Heat presses are versatile tools with a wide range of applications beyond just t-shirt printing. Heat press manuals should guide users on how to adapt the press for different materials and substrates, ensuring optimal results for each application.

For example, transferring designs onto mugs, plates, or other ceramic items requires different temperature and pressure settings than transferring onto fabric. The manual should provide specific instructions for each application, including⁚

- Temperature Settings⁚ Different materials have different heat tolerances. The manual should outline the recommended temperature for each application, ensuring that the transfer material adheres properly without damaging the substrate;

- Pressure Settings⁚ Applying the correct pressure is crucial for ensuring proper adhesion and preventing the transfer material from lifting or wrinkling. The manual should specify the appropriate pressure settings for each application.

- Time Settings⁚ The duration of the heat press application influences the transfer’s adhesion. The manual should provide time recommendations for various materials and substrates.

- Pre-Pressing and Post-Pressing Procedures⁚ Some applications may require pre-pressing or post-pressing steps to enhance adhesion or prevent warping. The manual should outline these procedures, if applicable.

- Specific Transfer Materials⁚ Different transfer materials, such as heat transfer vinyl, sublimation ink, or iron-on transfers, require specific temperature and pressure settings. The manual should provide guidance on using different transfer materials effectively.

By providing clear and comprehensive instructions for different applications, heat press manuals empower users to explore the full potential of their heat press, creating a wide range of personalized and customized products.